All In One Smart Factory Solutions

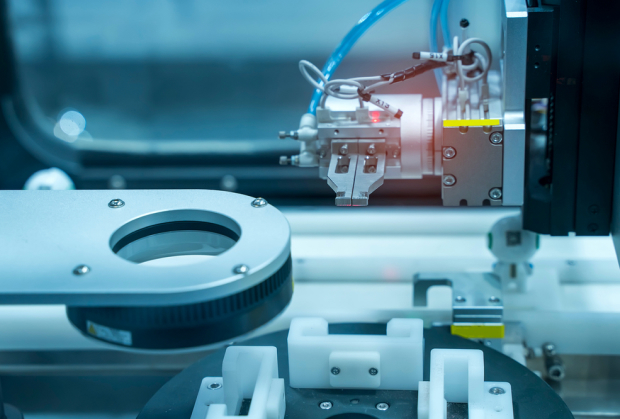

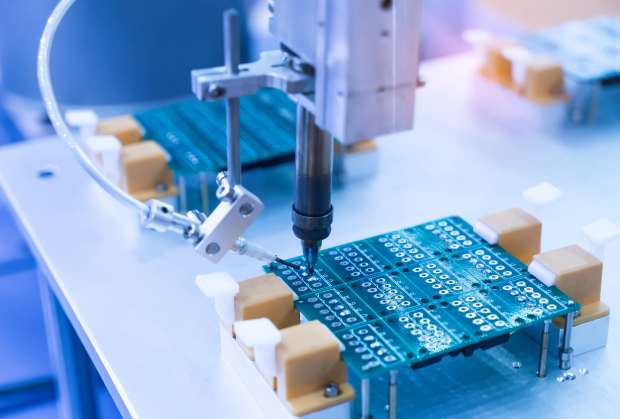

Wafer fabs need to shift from reactive to proactive maintenance strategies. It is reported unplanned downtime costs 10 times more than scheduled maintenance. G2 Technology presents the all-in-one smart factory solutions to meet the needs of the semiconductor and manufacturing industry.

rfid

remote control management

a.i driven automation

iot sensors

smart glass

Our smart factory solutions is designed

with these goals:

unscheduled

downtime

reliability and

availability of

production

assets

maintenance

costs

Our solution is customizable and can be retrofitted to integrate to your manufacturing systems.

It can enhance the system’s overall competencies by monitoring for defects, trigger points and anticipate

asset breakdown.

Introducing Dynamics 365 Remote Assist for

HoloLens 2 And Mobile Devices

The Five Smart Factory Solutions

Unleash The Power Of Automation With Our Cutting-Edge Smart Factory Solutions.

RFID

Remote Control Management

AI Driven Automation

Advanced AI driven scripts can automatically operate the equipment according to customer’s preset conditions and eliminate human errors.

IOT Sensors

Smart Glass

When a technician/engineer requires external support/guidance, they can wear-on Smart Glass for remote troubleshooting support while preventing confidential information from being exposed.

GUTC Trajectory Tracking of Robotic Arm

Features and Benefits

Features

- Information Theft Prevention

- Personal ID Double Authentication

- Shared Calibration Tools Tracking

- Intuitive User Interface

- Personnel Location Tracking System

Benefits

- Improve operational efficiency – reduce the need for non-valued added activities (e.g., gowning up, walking) & improve engineer to tool ratio (one control point to multiple equipment) and reduce cycle time

- Fast response to deescalate emergencies & minimize loss in production time.

- Data is protected (No data loss)

RFID

Remote Control Management

Features

- Local/Remote switch & lock - allows local priority and configurable users access control

- DLL controlled - efficient, modular architecture that ease deployment and installation.

- TCP/IP ensure no data can be transmitted from the equipment and RCM (central control room).

Benefits

- Improve operational efficiency

- Excellent data protection

- Secure access system

Features

- Automatically perform Scripts according to MES schedule.

- Communicate through MQTT or SECS/GEM to automatically control device

- Real-time capture for any production parameters of the screen data.

- Optical Character Recognition - perform Text, Image & Color recognition to do graphic comparisons

- User-Friendly Macro editing interface, flowchart like architecture to compile scripts

Benefits

- Increase productivity

- Prevent unexpected downtime

AI Driven Automation

Smart Glass

Features

- IP camera (Monitoring)

- Halo Lens (Troubleshoot with engineer supervision/guidance from the outside)

- Secure IP connection for external call

Benefits

- Improved efficiency in troubleshooting process

- Prevent data theft/infrastructure compromise

Features

- Real-time monitoring (24/7)

- Fault detection and alert

- Flexible sensor placement

- Data Acquisition

- Multi-sensor integration into customer’s manufacturing system process control chart

- Sensor application customization

Benefits

- Cost reduction (prevent un-expected downtime)

- Centralized control of data collected – ease of information retrieval

- Data collected can be use for process optimization

IOT Sensors